OGS full BEOL process substrates containing large front and rear sections of compulsory secondary cutting process .

Since the touch panel is provided by external pressure sensing components to carry out the action way to achieve the results, so the mechanical resistance to pressure is an important major manufacturers specification requirements and targets . The touch panel cutting secondary hardening of the classification process can generally be divided into two kinds of physically and chemically .

Physically , the prone after cutting edges of the glass cracking (chipping), the glass surface after cutting the rift segment is the use of abrasive trimming mode (polish) to strengthen the process for the second , the advantage is a good rate, mechanical resistance to pressure several times can significantly enhance the capacity , the disadvantage is the shape can not have too much glass cutting special shapes ( eg key hole and headphone hole ) , capacity is very low , do not have mass production , operation and requires a lot of manpower and machine equipment , and processes quite time-consuming, at least 30 minutes before shipment outputs .

Chemically intensive process but the use of hydrofluoric acid (Hydrofluoric Acid, HF) micro- etched glass cutting segment surface cracks special needs can be shaped not only cut the larger capacity , mass production of good, and the process takes only 7 ~ 8 minutes outputs a number of products , can enhance the mechanical resistance to pressure 4 to 8 times more , as long as the well-designed machine safety and smooth operation planning moving line , you can minimize the hazards of the job . Subsequent chemical industry equipment, processes two strong concepts derived mostly its way .

Secondary hardening chemical industry currently are used HF-resistant films were attached , the process flow in the OGS mother substrate (sheet) was cut into a finished product (chip) Thereafter, the acid-resistant film is attached to the chip , and then the chip device Cassette HF etched into the slot in the glass segment of facial micro etching process .

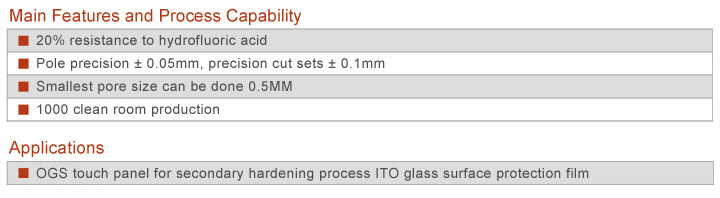

Division I currently use JC202HF acid-resistant film with excellent adhesion stability and peeling , no adhesive residue ; gum and ITO good compatibility , according to customer requirements, processing a variety of sizes , shapes acid-resistant film . Acid-resistant film 20% hydrofluoric acid resistance .