First, the protective membrane

Protective film structure: substrate layer ( surface ) , from the type of substrate on three factors .

The reason why the protective film a wide range of different characteristics , mainly by the different characteristics of these three factors and different combination.

.jpg)

★ protective film substrate

Currently protective film substrate selection are : PET, PE, modified PE, OPP, PVC and so on.

1) PET: good stiffness , surface smooth and clean high. Easy on the plastic coating, but the drawback is docile is bad .

2) PE: relatively soft , docile performance, commonly used in the irregular surface protection, but easy to stretch PE film ductility , tensile more difficult to control , PE protective film when the die size is easy to change , the product is easy to stretch the rubber layer rupture , causing adhesive residue. Meanwhile PE protective film is easy retraction, leaving waterlines phenomenon in the chassis .

3 ) Modified PE: PE film modified PE material has softness advantage than PE tensile membrane , it can be said that the modified PE material properties between the PET and PE : PE softness with both anti- PET LVL sex . Modified PE material protective film applications have broad market prospects .

4) OPP: OPP material softer , but its stretching is directional , the product is not easy to die , die finished at the point where the force is easy to tear , to the discharge of waste and operations difficult.

5) PVC: with "Cl", is not environmentally friendly .

★ protective film ----- Substrate: release paper, release film

1 ) Features a release paper : paper fiber surface texture rough.

2 ) Release Paper Features 2: air sensitive in the humidity.

3 ) Release Paper Features three: silicon transfer phenomenon , more stable residual adhesion release liner 80 %, while the residual film from the bonding strength more than 90% .

★ adhesive protective film

Currently two types of protective film Adhesive: acrylic ( acrylic ) , silicone , PU glue

Protective film adhesive surface treatment: 1 ) flat plastic surface , 2 ) point-like coating, 3 ) grid transfer adhesive .

Second, the common advantages and disadvantages of the protective film

1 , release paper substrate PET protective film

Advantages: low price , exhaust air , lower operating environment requirements .

Disadvantages: high gloss cabinet easy to produce silicon transfer phenomenon , slitting tension demanding affected by humidity , cutting edge products easy to produce pellets .

Comes with protective film release paper on the use of the attention point :

a, generally used in the ordinary painting, etching , matte surface casing , not suitable for use in high-gloss cabinet.

b, slitting to control the proper tension .

c, is not easy to do 30MM,30MM following products cutting thin strips , easily brought to the edge of particles produced intermediate products form a " residue " phenomenon.

2 , from the film substrate PET protective film

Advantages: high transparency, easy to produce plastic surface smooth cutting rubber , silicone transfer phenomenon minimal.

Disadvantages: rubber surface smoothing effects of exhaust performance plastic grid can solve this problem, because of the strong PET substrate itself is quite docile is bad .

Use Precautions : In the corner of a small plane or be affixed to use, small products do die .

3, PET silicone protective film

Advantages: plastic stability, high temperature, exhaust performance.

Disadvantages: Because silica adsorption protective film is so generally used in flat products .

Use Precautions : Use in high-gloss chassis.

4 , modified PEPE protective film

Pros: Easy sticking soft substrate than PE protective film tensile, easy adhesive residue.

Suggested Use: Preferred for use in the arc , have been affixed on the corner of Use . Such as a notebook front frame . PET and PE resolves too quite easily stretch issue.

5 , the mesh plastic protective film

Two processes : the grid and grid transfer method gluing

Pros: mesh plastic surface with good exhaust function.

There are two major categories of products : PET protective film and the modified grid mesh PE protective film , PET protective film to solve the grid plane and a large area of product problems , the modified PE protective film to solve a corner mesh products .

PU is an environmentally friendly protective PET film as the substrate, coated with PU adhesive , has a good adsorption , good stability, high light resistance, high weather resistance , low viscosity and easy to tear, high temperature , cleanliness high, for being affixed with excellent adhesive properties ; adhesive no adhesive residue after peeling , product transparency 90% ; optical grade PET material , good transmittance . Its re-use , and good air tightness , can be used for various optical parts and materials protection. Compared with the conventional protective film , low pollution , especially for the touch screen with the ITO glass processing , performance is better than ordinary silica protective film, resolves ordinary silica protective film mist and local unglued problem . Future protective film market , optical PU silicone protective film protective film will gradually replace the touch screen protective film to become the main market .

Performance Comparison of protective film

.jpg)

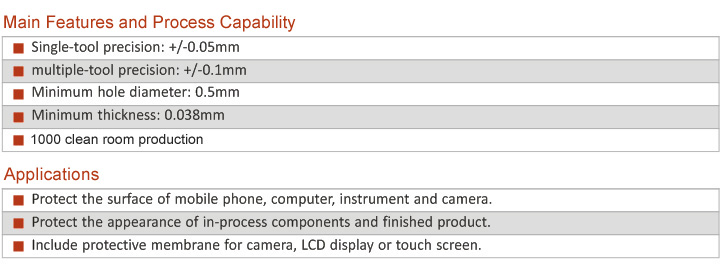

Due to increasing quantity and diversification of consumer electronics, the requirements on the clarity, resolution and cleanliness of display and touch screen is higher than before. Jincheng is able to provide a wide range of high-clarity protective membranes depending on close cooperation with well-known suppliers at home and abroad. We are also able to provide special-purpose protective membrane, such as anti-acid protective membrane, anti-static protective membrane, anti-peeping protective membrane, mirror protective membrane and colored protective membrane.